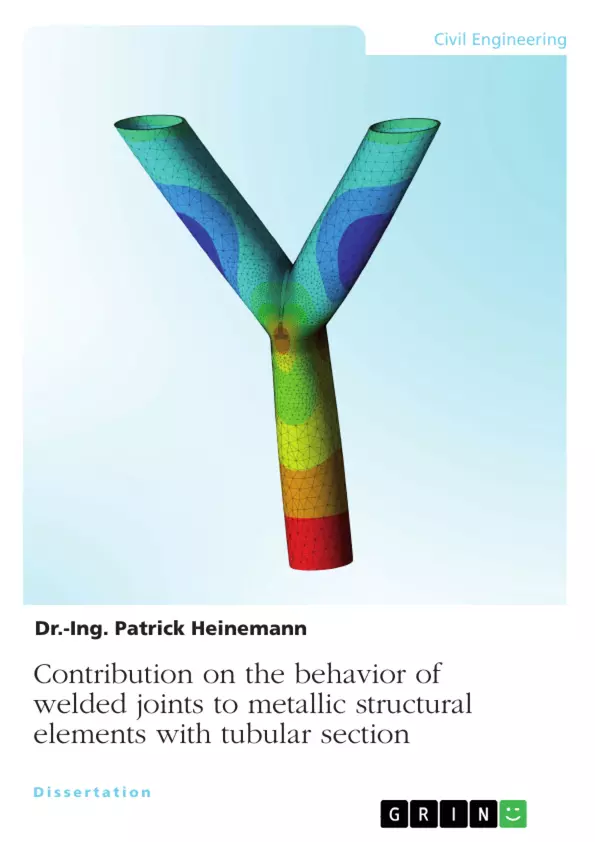

Steel structures, which are made of hollow section profiles are mainly used for construction structures. There are many fields of applications for structures made of hollow section profiles. Hollow section profiles are lightweight and have got a high resistance to compression, which is an advantage for column structures. The most common profile types have squared or circular hollow cross sections. Connecting two or more pipes by welding, the joints have got different shapes. These joints are part of trusses or columns with a tree-shaped optic. The standards have got restrictions regarding the geometry, material or load cases. By choosing a node, which is excluded in the standards, designing engineers have to create their own models. This thesis is about the designing of a Y-shaped steel joint, full overlapped on top connection, which is not defined in current standards up to the time the thesis is created. In this thesis only uniplanar joints are investigated. A special focus is on the welding line, which has got a three-dimensional shape. The aim is to figure out the influence on the inclination angle between the two members on the resistance of the joint. Beside this, the profile shape and profile thickness vary to see the differences in their resistance. Square and circular hollow section profiles are in focus. To analyse the behaviour of the different steel joints, a numerical and experimental investigation is executed. Design charts are created as a medium for designing engineers to calculate the ultimate resistance in the elastic and plastic state, depending on the steel profile, thickness and inclination angle. The structure of the thesis is split into four main parts. Firstly, there is an explanation of the general topic with its difficultness. Secondly, there is the state-of-the-art presentation of literature and standards in this range. Thirdly, there is a numerical analysis of the joints. The basement of the numerical studies is detailed in pre-studies, which explain and compare different mesh types or geometrical variations. Fourthly, there is an experimental verification of the numerical tests. It is figured out, if the inclination angle increase, the resistance of the steel joint will decrease significantly. This effect is non-linear. Beside this, it is found, that the full overlapped joint with the squared profile has got a higher resistance than a comparable joint with a similar circular hollow section.

Inhaltsverzeichnis (Table of Contents)

- Abstract

- Table of Content

- Table of Symbols and Variables

- Introduction

- Scope and objectives of the thesis

- The Novelty of the Subject

- Structure of the Thesis

- State of the Art

- Stress Distribution

- Standards

- Design Code Eurocode 3

- CIDECT

- FEA – Finite Element Analysis

- Numerical Analysation – Preliminary Case Studies

- Mesh Influence

- CHS Joint

- SHS Joint

- Three-Dimensional Column

- Two-Dimensional Column

- SHS Joint

- Symmetrical Model

- Asymmetrical Model

- CHS Joint

- Symmetrical Model

- Asymmetrical Model

- SHS Joint

- Expanded Geometry – With Top Plate

- Fixed Branch Length

- Symmetrical Model

- Asymmetrical Model

- Variable Branch Length

- Symmetrical Model

- Asymmetrical Model

- Fixed Branch Length

- Expanded Geometry – Without Top Plate

- Fixed Branch Length

- CHS Joint

- SHS Joint

- Variable Branch Length

- CHS Joint

- SHS Joint

- Fixed Branch Length

- Influence of Member’s Length & Result Comparison

- Results with top plate, fixed or expanded length

- Results with top plate, variable and expanded length

- Results without top plate, fixed length

- Results without top plate, variable length

- Mesh Influence

- Numerical Analysation - Case Study Small-Scale Model (Testing Model)

- CHS 2.0 mm Model

- CHS 2.8 mm Model

- SHS 2.8 mm Model

- Result Comparison

- Laboratory Test / Verification

- Description

- Testing Devices

- Compression Machine

- Strain Gauges

- Technical Specification

- Preparation & Conglutination

- Resistance Transducer (“LVDT”)

- Non-Destructive Tests

- Image Processing

- Liquid Testing

- Ultrasonic Testing

- Testing Specimen

- Description of the Specimen

- Flat Patterns

- Testing Setup

- Test Execution

- Results

- CHS Profile t = 2.0 mm

- CHS 2.0 mm – 20° Inclination Angle

- CHS 2.0 mm – 25° Inclination Angle

- CHS 2.0 mm – 30° Inclination Angle

- CHS 2.0 mm – 45° Inclination Angle

- CHS Profile t = 2.8 mm

- CHS 2.8 mm – 20° Inclination Angle

- CHS 2.8 mm – 25° Inclination Angle

- CHS 2.8 mm – 30° Inclination Angle

- CHS 2.8 mm – 45° Inclination Angle

- SHS Profile t = 2.8 mm

- SHS 2.8 mm – 20° Inclination Angle

- SHS 2.8 mm – 25° Inclination Angle

- SHS 2.8 mm – 30° Inclination Angle

- SHS 2.8 mm – 45° Inclination Angle

- Comparison of the experimental Results

- CHS Profile t = 2.0 mm

- Summary and Comparison of the Results

- Comparison of the Strain Results

- CHS 2.0 mm Profile

- CHS 2.8 mm Profile

- SHS 2.8 mm Profile

- Overall Strain Comparison

- Ultimate Resistance Y-joint

- Elastic – Elastic

- Plastic – Plastic

- Comparison of the Strain Results

- Discussion

- Comparison to Literature

- Comparison to Standard

- Comparison to Preliminary Studies

- Conclusion

- Future Studies, Outlook and Publications

- Future Studies and Outlook

- Publications

- Author’s Contribution

- Acknowledgment and Declaration of Authorship

- References

- List of Figures and Tables

Frequently Asked Questions

What is the main objective of this structural engineering thesis?

The thesis investigates the behavior and resistance of welded Y-shaped steel joints in tubular sections, specifically those not yet covered by current standards like Eurocode 3.

How does the inclination angle affect the joint's resistance?

The study found that as the inclination angle increases, the resistance of the steel joint decreases significantly in a non-linear fashion.

Which profile type showed higher resistance: CHS or SHS?

The research indicates that full overlapped joints with squared hollow sections (SHS) generally exhibit higher resistance than comparable circular hollow sections (CHS).

What methodologies were used to analyze the steel joints?

The analysis combined numerical simulations (Finite Element Analysis) with experimental laboratory tests for verification.

What are "design charts" in this context?

Design charts are tools created for engineers to calculate the ultimate resistance of joints in both elastic and plastic states based on profile thickness and angle.

- Quote paper

- Dr.-Ing. Patrick Heinemann (Author), 2022, Contribution on the behavior of welded joints to metallic structural elements with tubular section, Munich, GRIN Verlag, https://www.grin.com/document/1323678